Taconic RF-35 High Frequency Printed Circuit Board: DK 3.5 RF PCB Options (10mil, 20mil, 30mil, 60mil)

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Product Overview

Introducing the Taconic RF-35 High Frequency Printed Circuit Board, a premier choice for low-cost, high-volume commercial microwave and radio frequency applications. This PCB is constructed from an organic-ceramic laminate material from Taconic's ORCER family, characterized by:

Material Composition: Based on woven glass reinforcement and Taconic's advanced ceramic filling technology.

Peel Strength: Exceptional peel strength for ½ oz and 1 oz copper, essential for rework situations.

Thermal Properties: Glass transition temperature (Tg) exceeding 315°C.

Moisture Resistance: Ultra-low moisture absorption and low dissipation factor minimize phase shifts at high frequencies.

Dimension Stability: Woven fabric design ensures stable dimensions.

.jpg)

Copper Options

Our RF-35 PCBs come with electrodeposited copper options available in:

10mil,20mil,30mil,60mil

Benefits

By choosing RF-35, you gain advantages such as:

Cost-Effectiveness: Ideal for high-volume production.

Enhanced Performance: Excellent peel strength and low dissipation factors.

Surface Smoothness: Improved surface quality for better reliability.

Typical Applications

RF-35 PCBs are perfect for:

Power Amplifiers

Filters and Couplers

Passive Components

Our PCB Capability (RF-35)

| PCB Capability (RF-35) | |

| PCB Material: | PTFE Ceramic Fiberglass |

| Designation: | RF-35 |

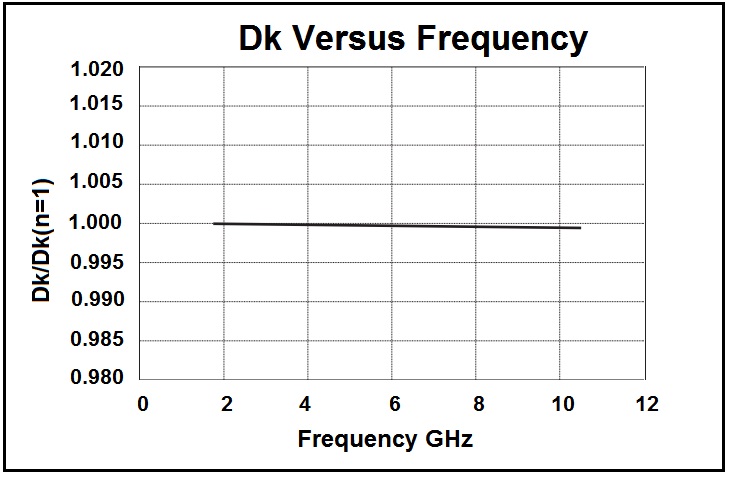

| Dielectric constant: | 3.5 |

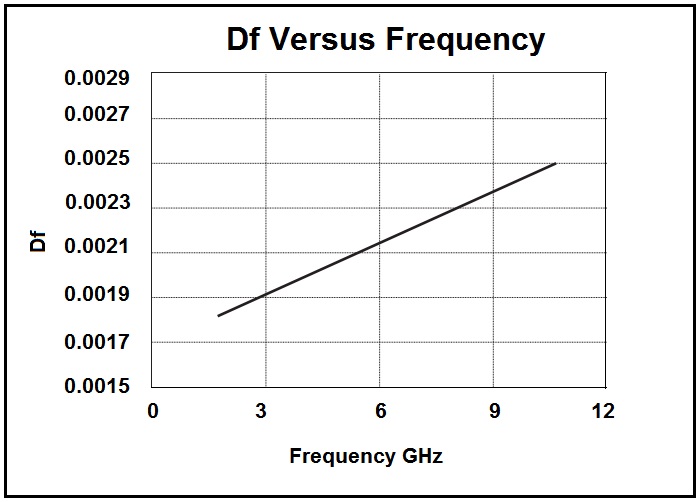

| Dissipation Factor | 0.0018 |

| Layer count: | Single Layer, Double Layer, Multilayer, Hybrid PCB |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| Laminate thickness: | 5mil (0.127mm), 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | Bare copper, HASL, ENIG, Immersion silver, Immersoin tin, ENEIPIG, Pure gold, OSP etc.. |

RF-35 Typical Value

| RF-35 Typical Values | |||||

| Property | Test Method | Unit | Value | Unit | Value |

| Dielectric Constant @ 1.9 GHz | IPC-TM 650 2.5.5 | 3.5 | 3.5 | ||

| Dissipation Factor @ 1.9 GHz | IPC-TM 650 2.5.5 | 0.0018 | 0.0018 | ||

| Moisture Absorption (.060") | IPC-TM 650 2.6.2.1 | % | 0.02 | % | 0.02 |

| Peel Strength (1/2 oz. copper) | IPC-TM 650 2.4.8 | lbs./linear inch | >8.0 | N/mm | >1.5 |

| Peel Strength (1 oz. copper) | IPC-TM 650 2.4.8 | lbs./linear inch | >10.0 | N/mm | >1.8 |

| Dielectric Breakdown | IPC-TM 650 2.5.6 | kV | 41 | kV | 41 |

| Volume Resistivity | IPC-TM 650 2.5.17.1 | Mohm/cm | 1.26 x 109 | Mohm/cm | 1.26 x 109 |

| Surface Resistivity | IPC-TM 650 2.5.17.1 | Mohm | 1.46 x 108 | Mohm | 1.46 x 108 |

| Arc Resistance | IPC TM 650 2.5.1 | seconds | >180 | seconds | >180 |

| Flexural Strength Lengthwise | ASTM D 790 | psi | >22,000 | N/mm2 | >152 |

| Flexural Strength Crosswise | ASTM D 790 | psi | >18,000 | N/mm2 | >124 |

| Thermal Conductivity | ASTM F 433 | W/m/K | 0.24 | W/m/K | 0.24 |

| Tensile Strength Lengthwise | ASTM D 638 | psi | 27,000 | N/mm2 | 187 |

| Tensile Strength Crosswise | ASTM D 638 | psi | 21,000 | N/mm2 | 145 |

| Dimensional Stability Lengthwise | IPC-TM 650 2.4.39 | in/in | 0.00004 | mm/mm | 0.00004 |

| Dimensional Stability Crosswise | IPC-TM 650 2.4.39 | in/in | -0.0001 | mm/mm | -0.0001 |

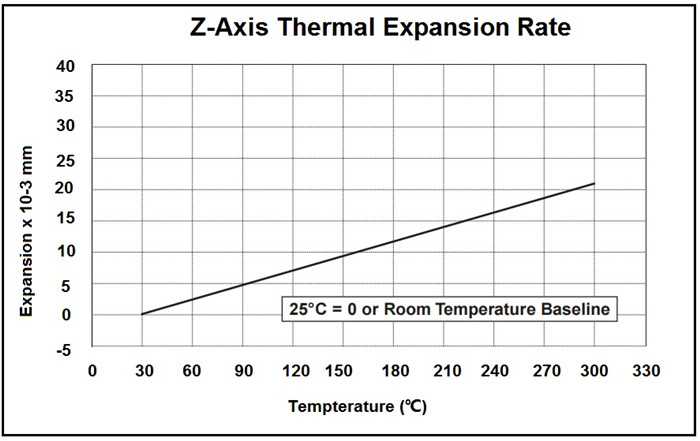

| x-y CTE | ASTM D 3386 (TMA) | ppm/°C | 19-24 | ppm/°C | 19-24 |

| z CTE | ASTM D 3386 (TMA) | ppm/°C | 64 | ppm/°C | 64 |

| Flammability | UL-94 | V-0 | V-0 | ||

| Hardness | Rockwell M Scale | 34 | 34 | ||

DK list

| Type | Dk | |

| TLY-5A | 2.17 | |

| TLY-5 | 2.20 | |

| TLY-3 | 2.33 | |

| TLT-0 | TLX-0 | 2.45 |

| TLT-9 | TLX-9 | 2.50 |

| TLT-8 | TLX-8 | 2.55 |

| TLT-7 | TLX-7 | 2.60 |

| TLT-6 | TLX-6 | 2.65 |

| TLE-95 | 2.95 | |

| TLC-27 | 2.75 | |

| TLC-30 | 3.00 | |

| TLC-32 | 3.20 | |

| RF-30 | 3.00 | |

| RF-35 | RF-35P | 3.50 |

| RF-60 | 6.15 | |

| CER-10 | 10 | |

Explore the capabilities of our RF-35 high frequency printed circuit boards today and elevate your design solutions!